Home/aluminium sheet/aluminum panel sheet

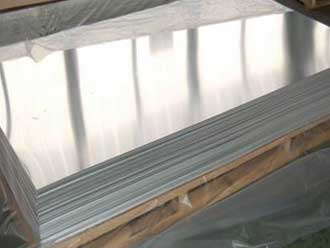

aluminum panel sheet

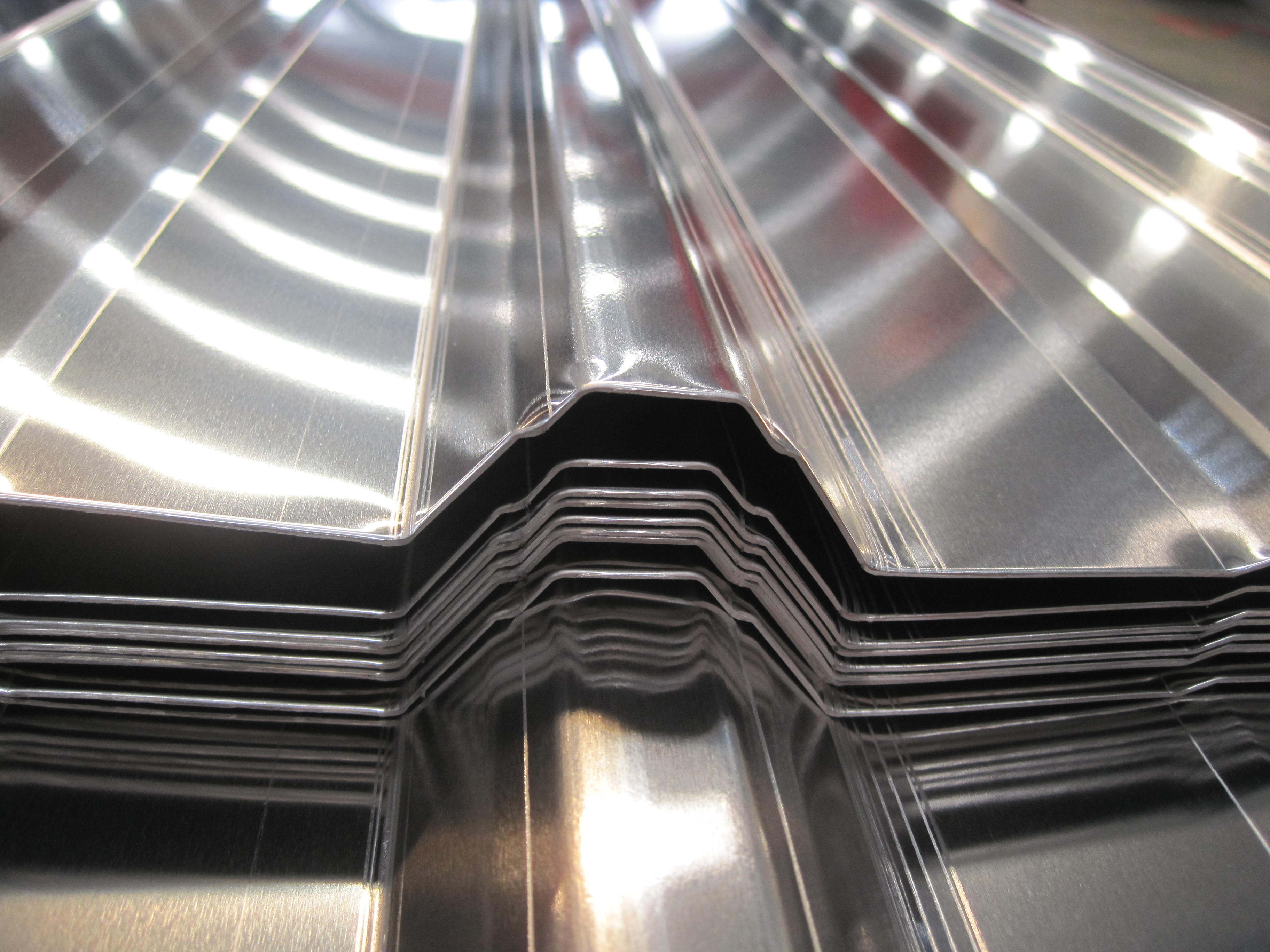

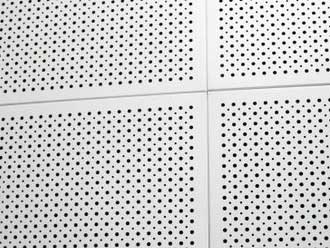

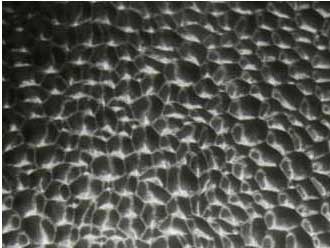

aluminum panel sheet as Aluminium Composite Panels are available in various widths & thicknesses depending upon the intended application. The range is further expanded into Fire Retardant and Stone Finish panels in attractive colours and patterns.

Specification

Substrates: |

Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

Thickness: |

0.08-4.0mm |

Width: |

<1800mm |

Coils core diameter: |

150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: |

PVDF >=25micron POLYESTER>=18micron |

Color standard: |

E < 2 or it is not obvious by eyeballing |

Pencil hardness: |

> 2HB |

Coating adhesive: |

not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend stength: |

>100 times |

Boiling point: |

no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: |

surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

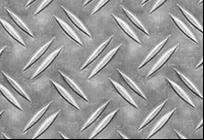

PE aluminum panel sheet(aluminum composite panel) structure is essentially composed of three layers which together along with a coating of PE combine to form a highly insulated flat panel. The two layers of aluminum sheets are bonded together permanently with an internal core of polyethylene which when coated through PE makes the surface even more flat and highly resistant. An important point is that only the front of the panel is coated with PE (Polyester) Paint so that maximum damage can be absorbed without damaging the interior core and sheet. The following are some of the feature of PE aluminum composite panel:

Specifications:

The thickness follows a standard guideline of measurements of 3, 4, 5 and 6mm which according to certain brands and preferences. As far as the width is concerned it ranges from 1000mm to 1750mm which makes the panel quite flexible and fulfills the requirements of personal usage. Furthermore, the length of the panel is also flexible as it ranges from 2440mm-5800mm which means that the panel can be used in a variety of forms.

Features and Applications:

PE coated aluminum panel sheet have unique features which makes them the first choice when it comes to having a panel that is weather resistant. Qualities such as durability, strength, fire resistant, sound insulation, heat insulation and alkali resistant make it a standout product. One important thing that needs to be remembered is that the installation process of PE coated panels is fast and efficient which makes the entire process easier.

There is a reason why PE coated aluminum panels have been in high demand over the last few years, this is because of the fact that PE coated panels present quite versatile options with consistent features. The most common applications of PE coated panels would be the usage in interior decorations, billboards & signs, usage in partitions of rooms, low building claddings and ceilings. One of the biggest advantages of PE panels is the fact that they come out in a variety of colors for this sole reason the usage of PE panels in kitchens and rooms is also common.