Home/aluminium sheet/Aluminum roofing sheet

Aluminum roofing sheet

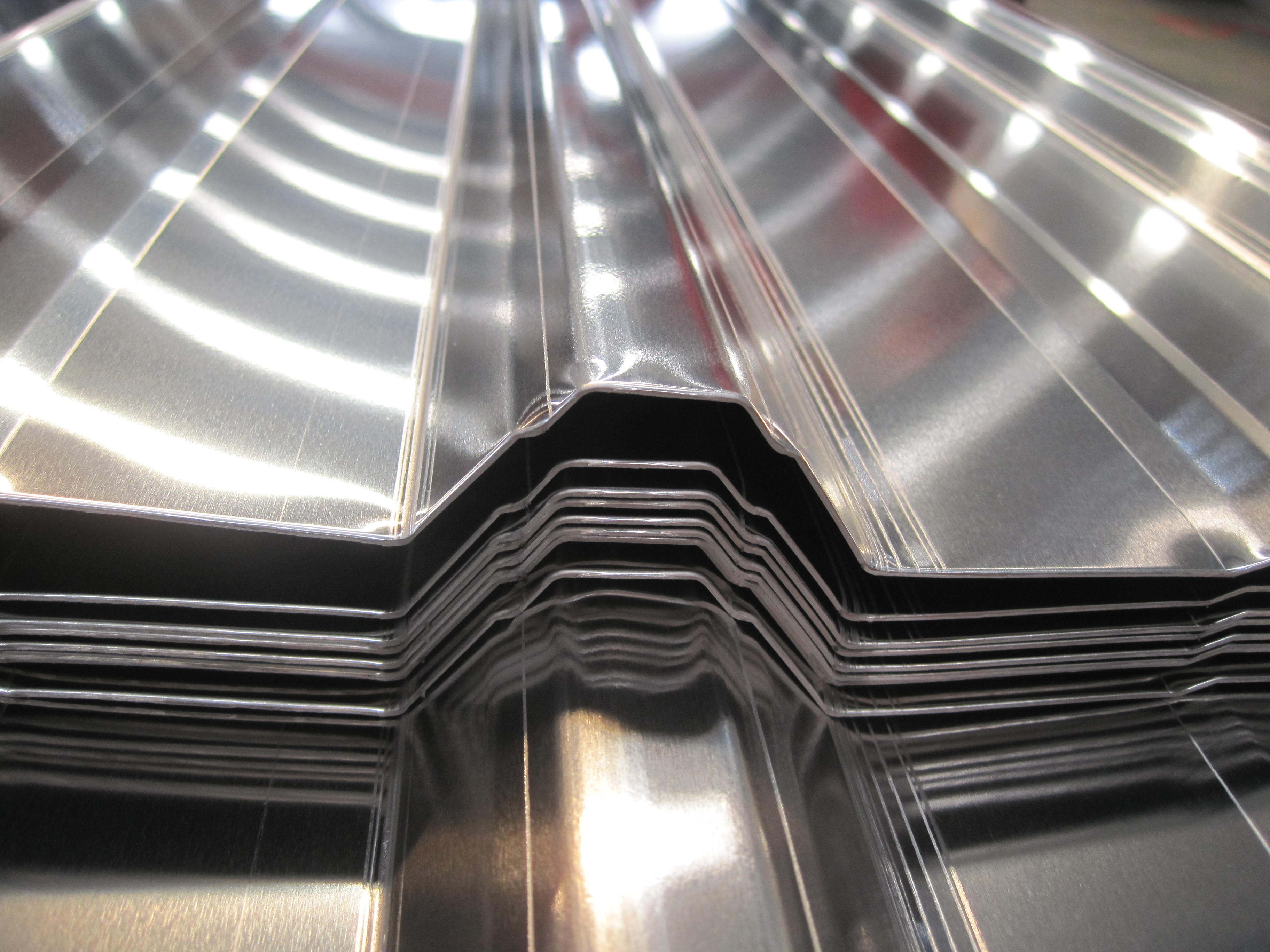

Aluminum roofing sheet also known as Corrugated aluminum plate, pressed aluminum plate, corrugated aluminum sheet or aluminum tile. It is one of the commonly used products in building, currently it is more and more popular, and has a tendency to replace stainless steel and iron plate.

HAOMEI uses quality Falzonal for aluminum roofing and aluminium wall cladding applications. Falzonal and our aluminum are excellent cost effective solutions for extreme roofing environments and come with a baked on paint system to suit all your architectural requirements.

All HAOMEI Aluminium has been manufactured to meet the strict Standards (YS/T431-2009) and is warranted by HAOMEI for up to 20 years on Roofing and Wall Cladding applications.

It is easy to maintain and can be washed easily.

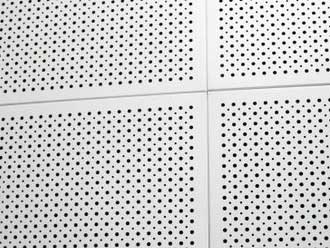

The advantages of aluminum suspended ceilings:

- the ability to create radical ceilings

- high resistance to corrosion

- Non-flammable, waterproof

- environmentally friendly material

- types of coating: glossy

The company Haomei Industrial Co., Ltd. manufactures and offers the following conditions:

Product Specification

Alloy |

AA 3003 /EN AW-3004 |

|

|||||

Temper |

H41, H44 |

||||||

Dimensions |

|

||||||

Specific weight: |

1,9 kg/m² |

||||||

Tensile strength |

130 - 170 N/mm2 |

||||||

Proof Stress |

> 100 N/mm2 |

||||||

Elongation |

> 6% |

||||||

Thermal expansion: |

Coefficient of linear expansion: 0,024 mm/m/K |

||||||

Elasticity: |

Modulus of elasticity: -70.000 MPa |

||||||

Fire protection: |

Non-combustible according to EN 13501-A1. Smoke gases comply with DIN 4102 and pose no threat to health. |

||||||

Gloss |

10 or 20 units in the Gardner system, meauring angle 60°,metallic colours with approx 40units. |

||||||

Colour range |

Colours as per current HAOMEI colour chart basis on RAL no, with various special colour developments such as simulated copper, titanium to zinc. Minimum quantitied for special colours and special customised tones 1500㎡ |

||||||

Protective film |

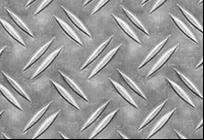

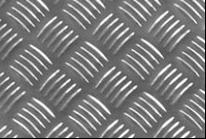

Anti-slip, white, UV-resistant, asymmetrically-perforated protective film. |

||||||

Coating: |

Front face |

(exposed side): 2-layer system (primer and top coat applied using coil-coating process). |

|||||

Paint-system |

PVDF (polyvinylidene fluoride). |

||||||

Reverse face |

transparent protective lacquer with printed identification No. and RAL NO. An arrow indicates the direction of coating. |

||||||

Aluminum roofing sheet Surface

Front Face:

HAOMEI Aluminum roofing sheet pre-painted aluminium coil for roof has been coil coated with a PVDF paint system (80/20). The paint thickness is approx. 25µm for a two layer paint system. For special coatings the paint thickness is approx. 40 µm.

Reverse side:

The reverse side of HAOMEI Aluminum roofing sheet is provided with a transparent protective lacquer, thickness approx. 3µm. This protective lacquer is suitable for gluing and foaming. Transparent protective lacquer with HAOMEI symbol.

Protective film:

HAOMEI Aluminum roofing sheet is delivered with a patented, asymmetrically perforated anti-slip protective film for the front side. This protection film is UV-resistant and can remain on the panels for up to six months until all work is complete.

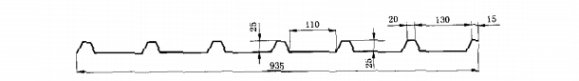

picture 1: V 25-150 ⅰ

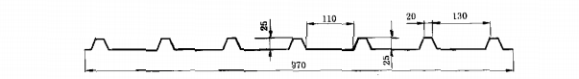

picture 2: V25-150 ⅱ

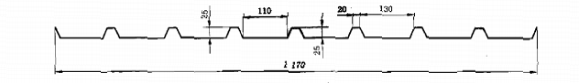

picture 3: V25-150 ⅲ

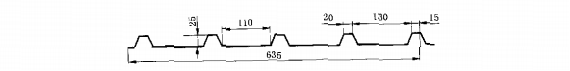

picture 4: V25-150 ⅳ

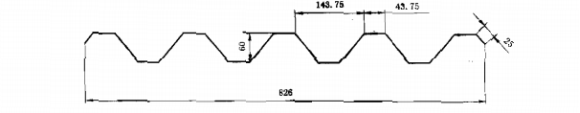

picture 5: V60-187.5

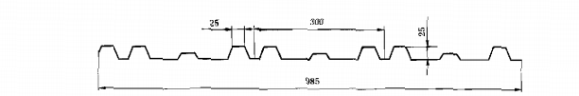

picture 6: V25-300

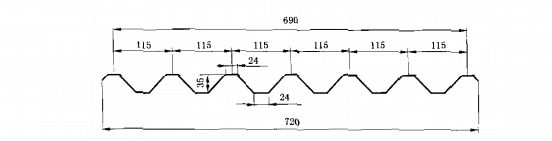

picture 7: V35-115 ⅰ

picture 8: V35-115 ⅱ

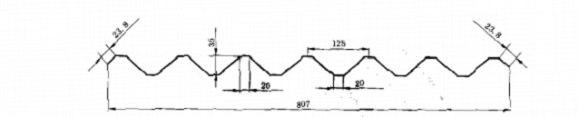

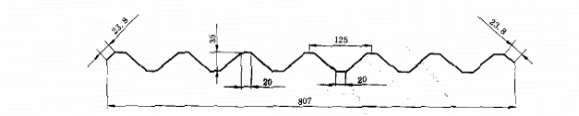

picture 9: V35-125

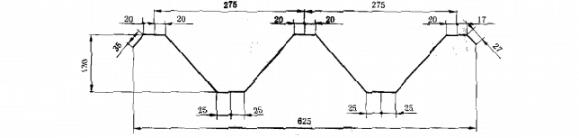

picture 10: V130-550

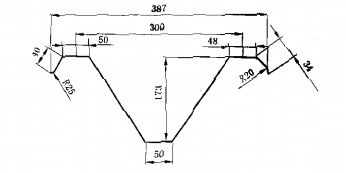

picture 11: Y173

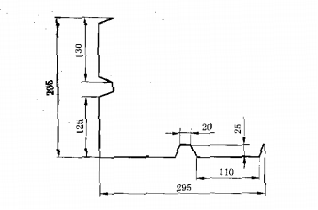

picture 12: Z295