Home/aluminium sheet/6061 aluminum sheet

6061 aluminum sheet

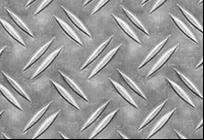

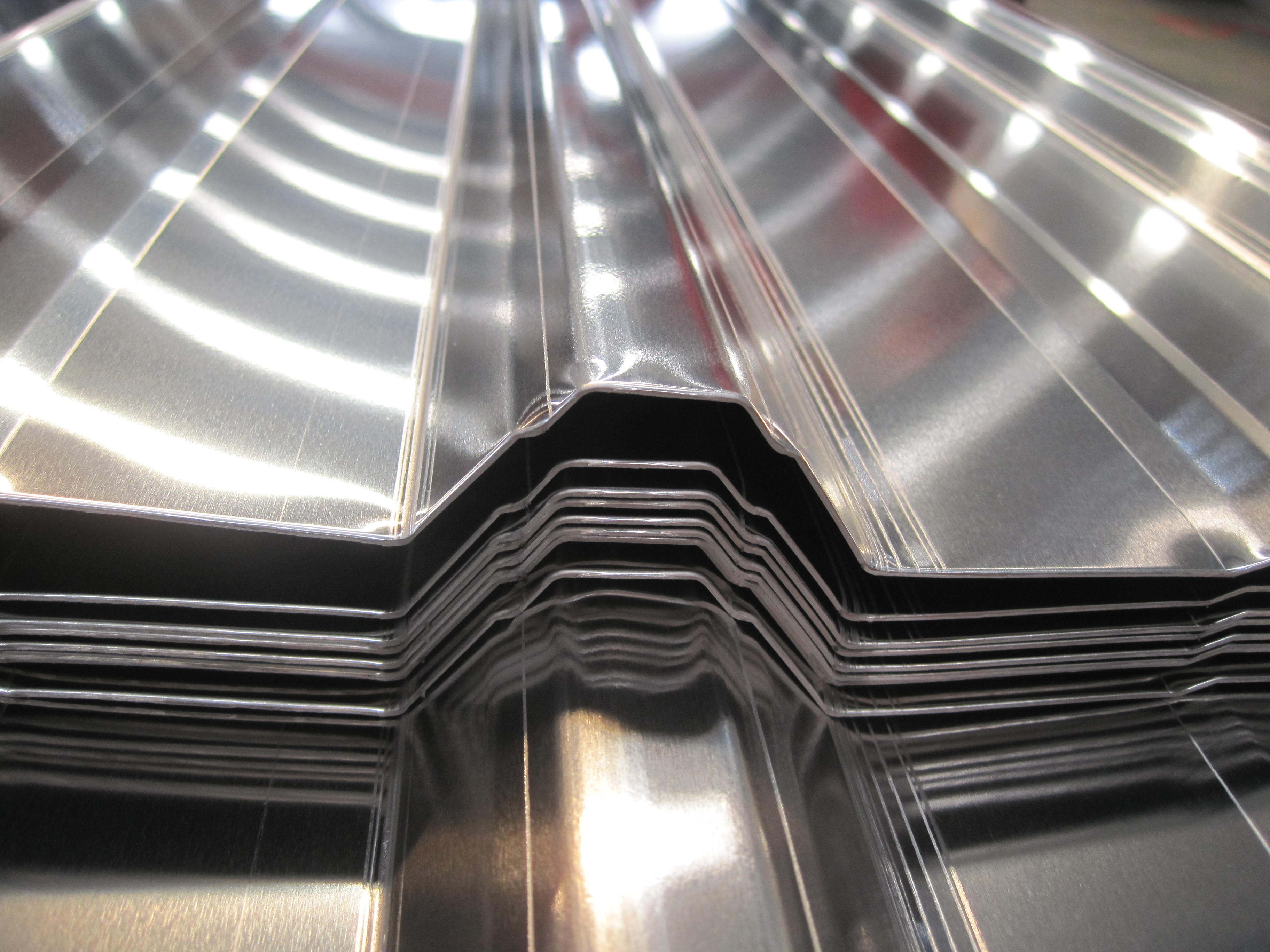

6061 aluminum sheet is one of the advantages of aluminum products, aluminum research and development of the "1+1" hot rolling production line, is specifically for the Aluminum sheet, the 2 series, the 7 series, the series of aluminum and other high-end products in the production line of research and development in. 6061 aluminum sheet processing technology of Haomei aluminum production far more than counterparts, the thinnest can produce 0.6mm, the aluminum oxide has a good effect after processing, small deformation, uniform quenching and other advantages, in the mobile phone shell, automobile hub, rod boxes, 3C products and other fields, enjoys a good reputation and reputation. At the same time, the 6061 aluminum sheet of Haomei aluminum industry, with its excellent quenching performance, superior corrosion resistance and other advantages, has been widely used in the field of automobile, aerospace, shipbuilding and other fields.

Alloy |

Temper |

Thickness(mm) |

width(mm) |

length(mm) |

Final usage |

6061 aluminum sheet |

O, T4, T6, T651 |

0.3-600 |

500-2600 |

500-16000 |

Mobile phone shell, mobile phone board, card slot, aerospace, automobile |

6061 aluminum alloy Properties

| 6061 | Annealed 6061 aluminum alloy (6061-O temper) has maximum tensile strength no more than 120 MPa (18,000 psi), and maximum yield strength no more than 55 MPa (8,000 psi). The material has elongation (stretch before ultimate failure) of 25–30%. |

|---|---|

| 6061-T4 | T4 temper 6061 alloy has an ultimate tensile strength of at least 210 MPa (30,000 psi) and yield strength of at least 110 MPa (16,000 psi). It has elongation of 16%. |

| 6061-T6 | T6 temper aluminum alloy 6061 has an ultimate tensile strength of at least 290 MPa (42,000 psi) and yield strength of at least 240 MPa (35,000 psi). More typical values are 310 MPa (45 ksi) and 270 MPa (39 ksi), respectively. In thicknesses of 6.35 mm (0.250 in) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties. The typical value for thermal conductivity for 6061-T6 at 25 °C (77 °F) is around 152 W/m K. A material data Aluminum sheet defines the fatigue limit under cyclic load as 97 MPa (14,000 psi) for 500,000,000 completely reversed cycles using a standard RR Moore test machine and specimen. Note that aluminium does not exhibit a well defined "knee" on its S-n graph, so there is some debate as to how many cycles equates to "infinite life". Also note the actual value of fatigue limit for an application can be dramatically affected by the conventional de-rating factors of loading, gradient, and surface finish. |

Performance advantage:

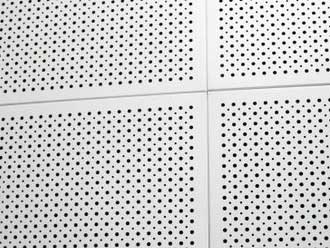

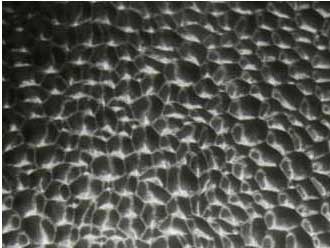

1, 6061 aluminum sheet has excellent processing performance, good corrosion resistance, high toughness and deformation after processing, easy coating, good oxidation effect and other excellent features, after annealing can still maintain a good operability. In particular, the tendency of non stress corrosion cracking, good weldability, good cold workability

2, Advanced equipment 3000T tensile machine, according to process requirements, 1.0%--3.0% on the plate within the stipulated time of permanent tensile plastic deformation, the elastic deformation to plastic deformation, to eliminate the residual stress after quenching, ensure product deformation in machining

3, In the process of customer cooperation Haomei aluminum summed up the customer's specific requirements for the 6061 aluminum sheet :

(1) the required thickness tolerance is small (usually positive).

(2) hardness should be up to (above HB).

(3) the deformation after processing is small.

(4) smoothness is better.