Home/Aluminium Strip /Aluminium Strip for Transformers

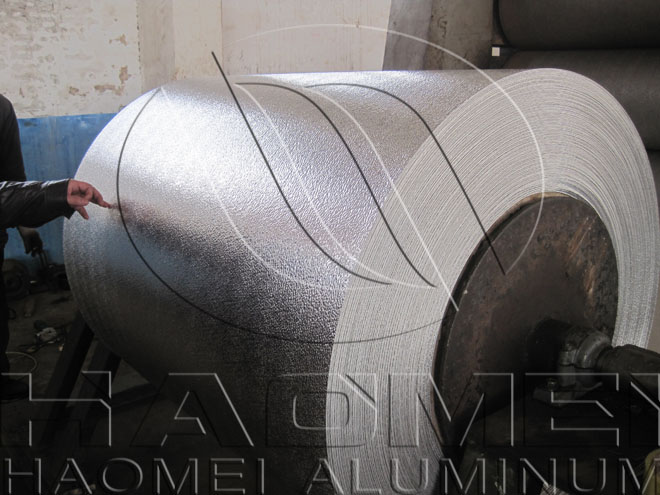

Aluminium Strip for Transformers

AT ISSUE There is a common misconception that a distribution transformer with copper windings is in some way more efficient, more reliable, or has higher short circuit strength when compared to a transformer with aluminum windings. RECOMMENDATION Improvements in technology regarding the use of aluminum in transformers have made aluminum-wound transformers the ideal choice for today’s applications. RATIONALE Operating Cost - Cooper Power Systems designs aluminum-wound transformers with windings of a larger cross-sectional area than would be used for a copper wound unit. This larger cross-sectional area translates to a lower current density, and an equivalent operating temperature. By reducing the current density in the windings, a low-loss design can be achieved with aluminum or copper windings. Reliability - A transformer’s life is defined by the life of its insulation system. Because Cooper aluminum-wound and copper-wound units run at equivalent operating temperatures, the insulation systems age at the same rate for each design. Lower Cost First - Whether low losses are the goal or not

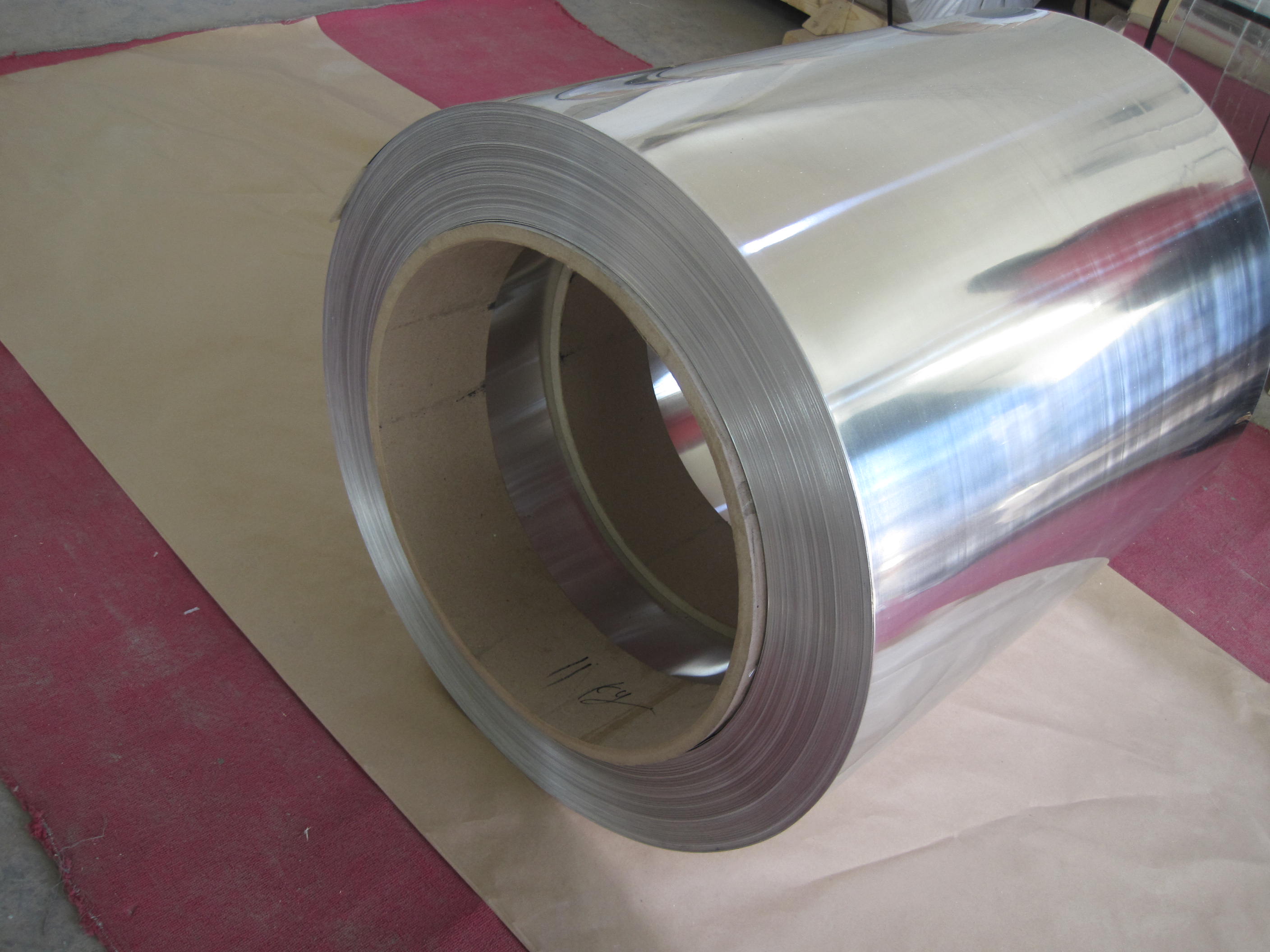

Specification

| Alloy | Temper | Thickness, мм | Tolerance, мм | Width, мм | Tolerance, мм |

| 1050, 1060, 1070, 1350 | О | 0,2-0,4|0,4-0,8|0,9-1,1|1,2-1,6|1,8-2,5 | ±0,01 ±0,015 ±0,02 ±0,025 ±0,03 | <100 100-200 201-500 501-1250 >1250 | ±0,1 ±0,2 ±0,2 ±1 ±2 |

Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 |

| 1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 |

| 1350 | 0.10 | 0.40 | 0.05 | 0.01 | - | 0.01 | - | 0.05 | 0.03 | - | - | 0.03 | 99.50 |

Application

|

|