Home/Aluminum Plate/7075 aluminum plate

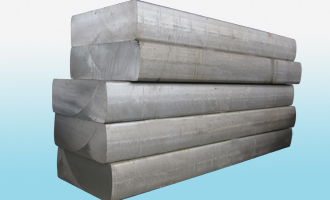

7075 aluminum plate

7075 aluminum plate belongs to Al-Zn-Mg-Cu super hard alloy is a kind of cold forging processing, high strength, high hardness, far better than mild. The alloy has good mechanical properties and anode reaction, which is a typical aluminum alloy material used in aerospace industry.

This 7075 aluminium plate is made of one of the strongest of the aluminum alloys. Its use parallels that of 2024, with 7075 selected when higher mechanical properties are desired. 7075 aluminum is an aluminum-zinc alloy with 1%-8% zinc in addition to small amounts of magnesium and small quantities of copper and chromium. This alloy is precipitation hardened to very high strength levels. Alloy 7075 is used in airframe structures and other highly stressed components. As a kind of cold finished wrought alloy, it has great strength and hardness. It’s far better than mild steel. This alloy has good mechanical properties and anode reaction. 7075 aluminum sheet as a typical kind of aerospace aluminum alloy material is usually used for high-end fields. 7075 aluminium alloy's composition roughly includes 5.6–6.1% zinc, 2.1–2.5% magnesium, 1.2–1.6% copper, and less than a half percent of silicon, iron, manganese, titanium, chromium, and other metals. It is produced in many tempers, some of which are 7075-0, 7075-T6, 7075-T651.

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Length(mm) |

Final usage |

7075 Aluminum Plate |

O、T6、T651 |

0.2-300 |

<1500 |

<8000 |

High son ball head, mold, aircraft landing gear, etc. |

Typical Mechanical Properties

| Temper | Tensile Strength KSI | Yield Strength KSI | Elongation % |

|---|---|---|---|

| 7075-O | 33 | 15 | 16 |

| 7075-T6 | 83 | 73 | 11 |

The mechanical properties of 7075 alloy depend greatly on the temper of the material

| 7075-0 | Un-heat-treated 7075 alloy plate(7075-0 temper) has maximum tensile strength no more than 280 MPa (40,000 psi), and maximum yield strength no more than 140 MPa (21,000 psi). The material has an elongation (stretch before ultimate failure) of 9–10%. It is very highly corrosion-resistant and has good strength |

|---|---|

| 7075-T6 | T6 temper 7075 alloy plate( has an ultimate tensile strength of 510–540 MPa (74,000–78,000 psi) and yield strength of at least 430–480 MPa (63,000–69,000 psi). It has a failure elongation of 5–11%. The T6 temper is usually achieved by homogenizing the cast 7075 at 450 °C for several hours, quenching, and then aging at 120 °C for 24 hours. This yields the peak strength of the 7075 alloy. The strength is derived mainly from finely dispersed eta and eta' precipitates both within grains and along grain boundaries |

| 7075-T651 | T651 temper 7075 has an ultimate tensile strength of 570 MPa (83,000 psi) and yield strength of 500 MPa (73,000 psi). It has a failure elongation of 3–9%. These properties can change depending on the form of material used. Thicker plate may exhibit lower strengths and elongation than the numbers listed above. |

| 7075-T7 | T7 temper has an ultimate tensile strength of 505 MPa (73,200 psi) and a yield strength of 435 MPa (63,100 psi). It has a failure elongation of 13%. T7 temper is achieved by overaging (meaning aging past the peak hardness) the material. This is often accomplished by aging at 100–120 °C for several hours and then at 160–180 °C for 24 hours or more. The T7 temper produces a micro-structure of mostly eta precipitates. In contrast to the T6 temper, these eta particles are much larger and prefer growth along the grain boundaries. This reduces the susceptibility to stress corrosion cracking. T7 temper is equivalent to T73 temper. |

| 7075-RRA | The retrogression and reage (RRA) temper is a multistage heat treatment temper. Starting with a sheet in the T6 temper, it involves overaging past peak hardness (T6 temper) to near the T7 temper. A subsequent reaging at 120 °C for 24 hours returns the hardness and strength to or very nearly to T6 temper levels. RRA treatments can be accomplished with many different procedures. The general guidelines are retrogressing between 180–240 °C for 15 min 10 |

Physical properties for aluminium alloy 7075

| Density (lb / cu. in.) | 0.101 |

|---|---|

| Specific Gravity/code> | 5.81 |

| Melting Point (Deg F) | 900 |

| Modulus of Elasticity Tension | 10.4 |

| Modulus of Elasticity Torsion | 3.8 |

Performance advantage:

1, After the elimination of stress, processing will not deformation, warping. All super thick 7075 aluminum plate by ultrasonic detection, can ensure no blisters, impurities. 7075 aluminum plate of high thermal conductivity, can shorten the molding time, improve work efficiency.

2, 7075 aluminum plate sheet has good physical properties, processability and corrosion resistance is good, the use of age hardening can get high strength;

3, Even if the natural aging, 7xxx alloy can also achieve a very high strength, low sensitivity to crack;

4, The welding part of the heat effect, due to the heating was dissolved, so after the natural aging, the strength can be restored, so as to improve the strength of the weld seam.

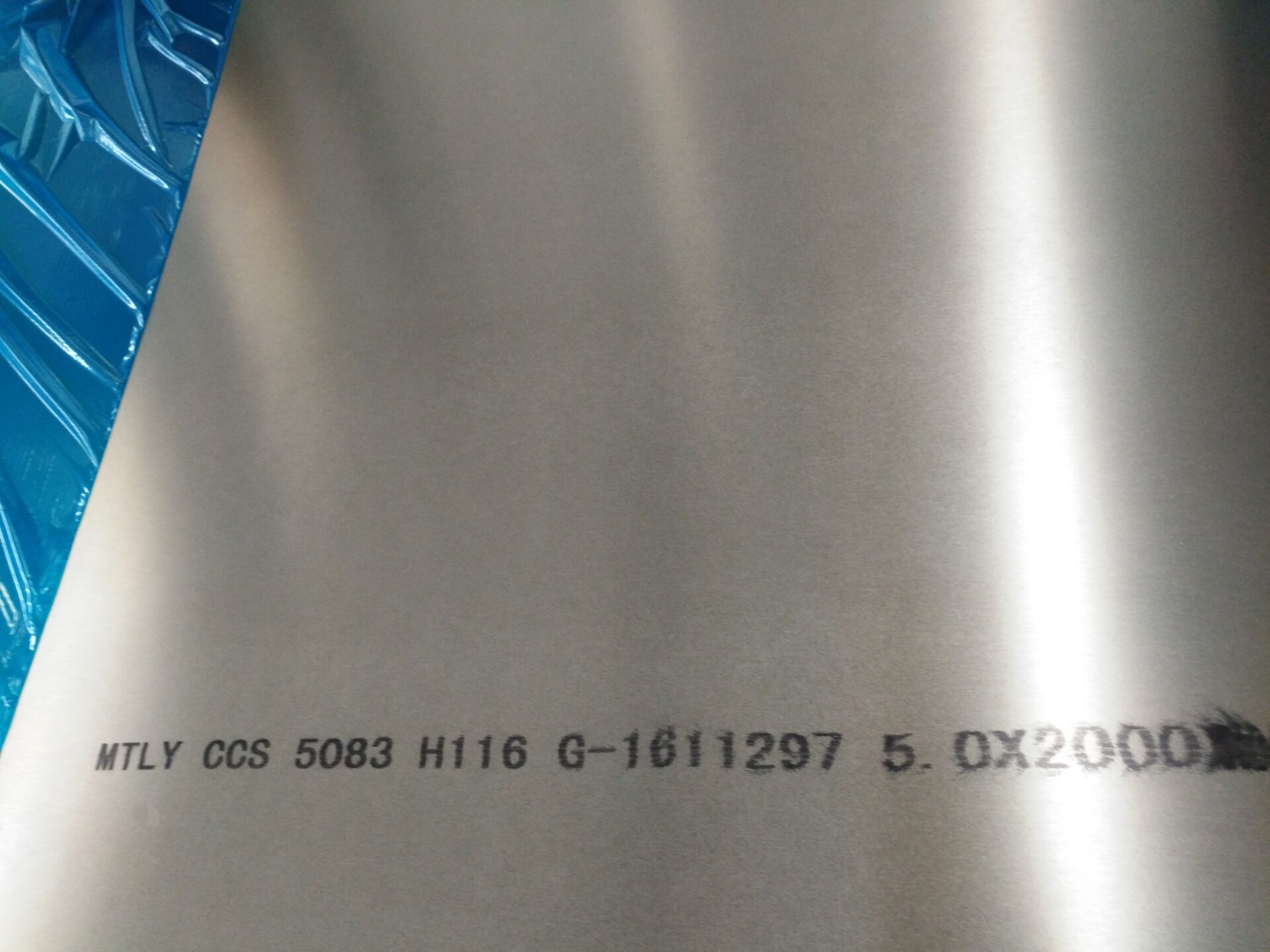

haomei aluminium is both a 7075 aluminium plate manufacturer and supplier with 18 years experience. So factory price is available. Besides, we use the finest raw material to improve the product quality, and we are certificated to CCS (China Classification Society) and DVN GL (Norske Veritas), guaranteeing the quality of our 7075 aluminium plate lives to national standards. haomei aluminium can manufacture 7075 aluminium plate with many tempers, such as O、T6、T651、T7451O、T6、T651、T7451 etc., and it can be cut to size at customers’ need.

The company Haomei Industrial Co., Ltd. China's largest Aluminum Plate manufacturers and suppliers, the production of 1-8 series aluminum alloy plates to provide you with the best price and high quality services

Haomei Aluminum Plate a variety of aluminum alloy plate grades and sizes tailored to your needs and specifications.